Our Process

Manufacturing specialist of ceramic core

Expertise in ceramic injection moulding

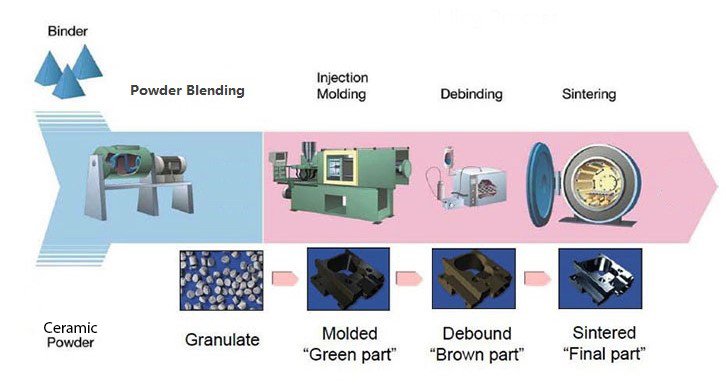

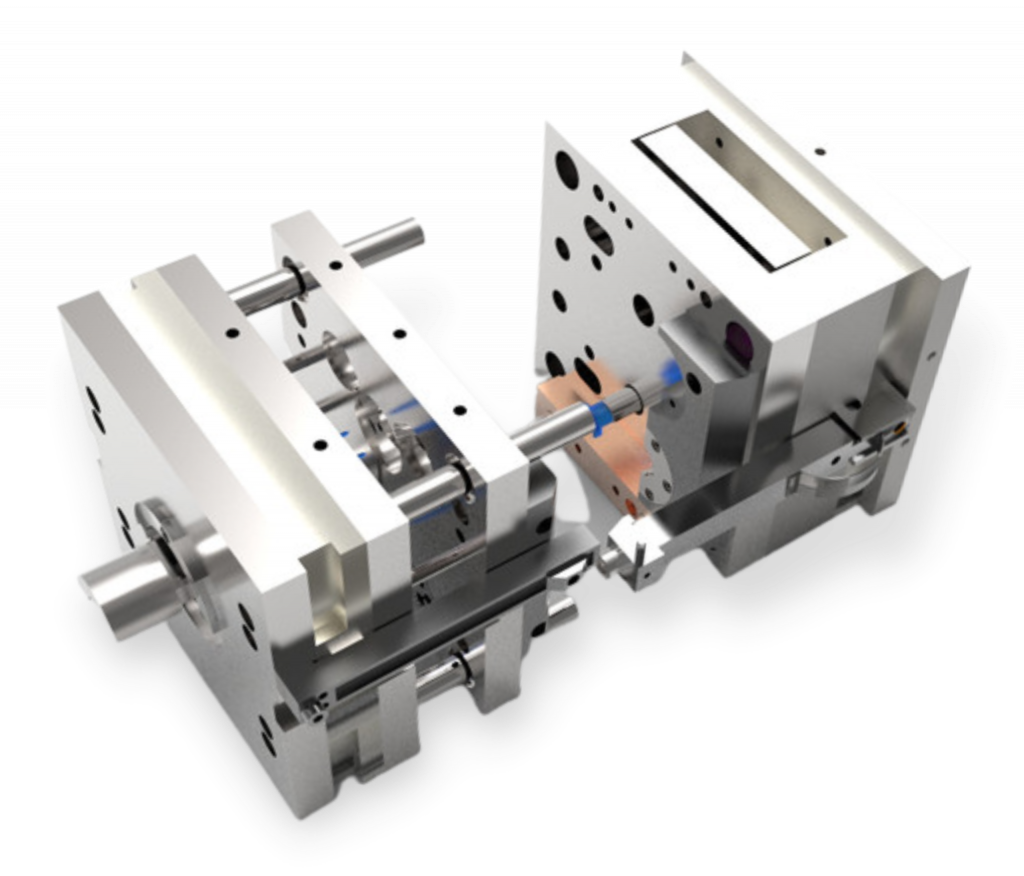

Salentec specializes in the process of injection moulding metallic and ceramic polymeric materials. In particular, it excels in developing components in technical ceramic material for injection (CIM). The experience developed starts from the composition of injectable ceramic feedstocks, to the dewaxing and sintering phases. Various ceramic compositions have been developed for aerospace, jewellery porcelain, zirconia and alumina components.

Compounding

Salentec produces ceramic raw materials and can offer customized products. The material selection, the composition of the ceramic powders and the binder components are adapted to the component and application requirements. Salentec combines knowledge and experience with technical advice on all production aspects of the injection moulding process.

Ceramic injection

molding facilities

Salentec factory in Lecce(IT) extends to over 1.200 sqm.

Facilities include a mould warehouse, QC laboratory, mixing, injection, firing, inspection, finishing, CMM, strengthening, packing and shipping equipment.

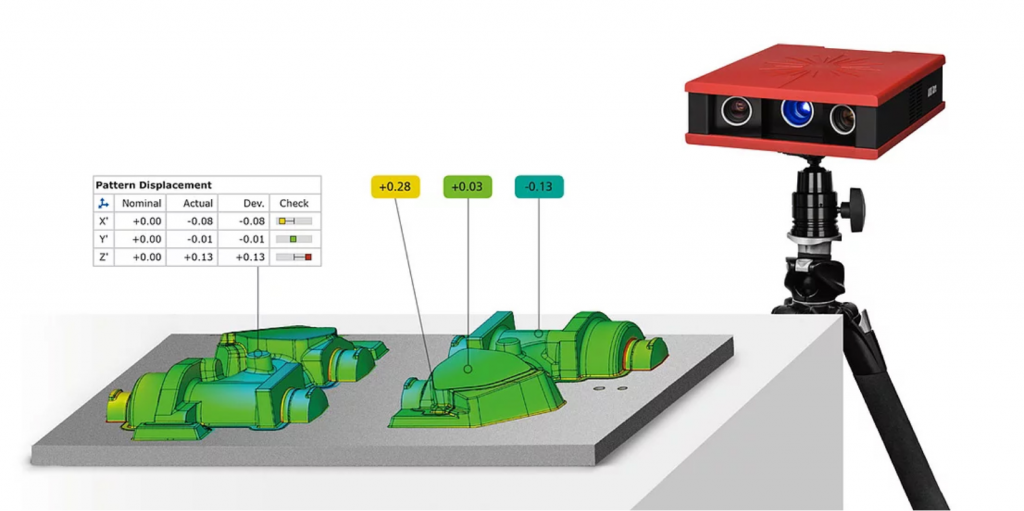

Recent investments include new kilns, mixers, presses, and 3D optical scanner doubling existing capacity.

Salentec currently employs workers with additional QA, QC, technical, and site engineers.

Sintering

The debinding and sintering cycles of the furnaces are managed with sophisticated cycle controllers; the thermal cycles are monitored and recorded continuously in each load of the furnace. Each load is instrumented with additional thermocouples for recording the temperatures in the different areas of the furnace. We have several sintering and debinding furnaces from 30 liters up to 1500 liters.

Finishing and visual inspection

The process of ‘hand finishing’ is very time consuming, very manual, very costly and generates a number of health and safety considerations. When there is a regular high-volume requirement from a customer then it is of course possible to use CNC machines to remove the internal split line from fine features and pedestal holes. The the CNC technology being used is always advancing and the ability of suppliers to ‘finish’ high volumes of complex cores is always improving. When CNC finishing of ceramic cores is done well it brings several benefits:

– Cost reduction

– Improved accuracy

– Improved repeatability

– Improved efficiency

– Reduced repetitive strain risks for the operators

Strengthening

The ceramic cores can be reinforced if necessary with urea, resin, with dedicated polymers. Depending on the geometry / section of the core, the resistances can generally be improved by a factor of 2 to 5 times higher.

Quality control and dimensional inspection

Inspection by non-destructive testing (NDC) using a blue methylene solution;

– Dimensional control by mechanical accessory (P / N gauge, shutter gauge)

– Dimensional control through structured light 3D scanner (GOM Precise Industrial 3D Metrology);

– Characterization of ceramic components (density, porosity, mechanical properties, et al.)